Embracing Slower Times - Part 3: Applying 5S for Long-Term Success

Annah Godwin

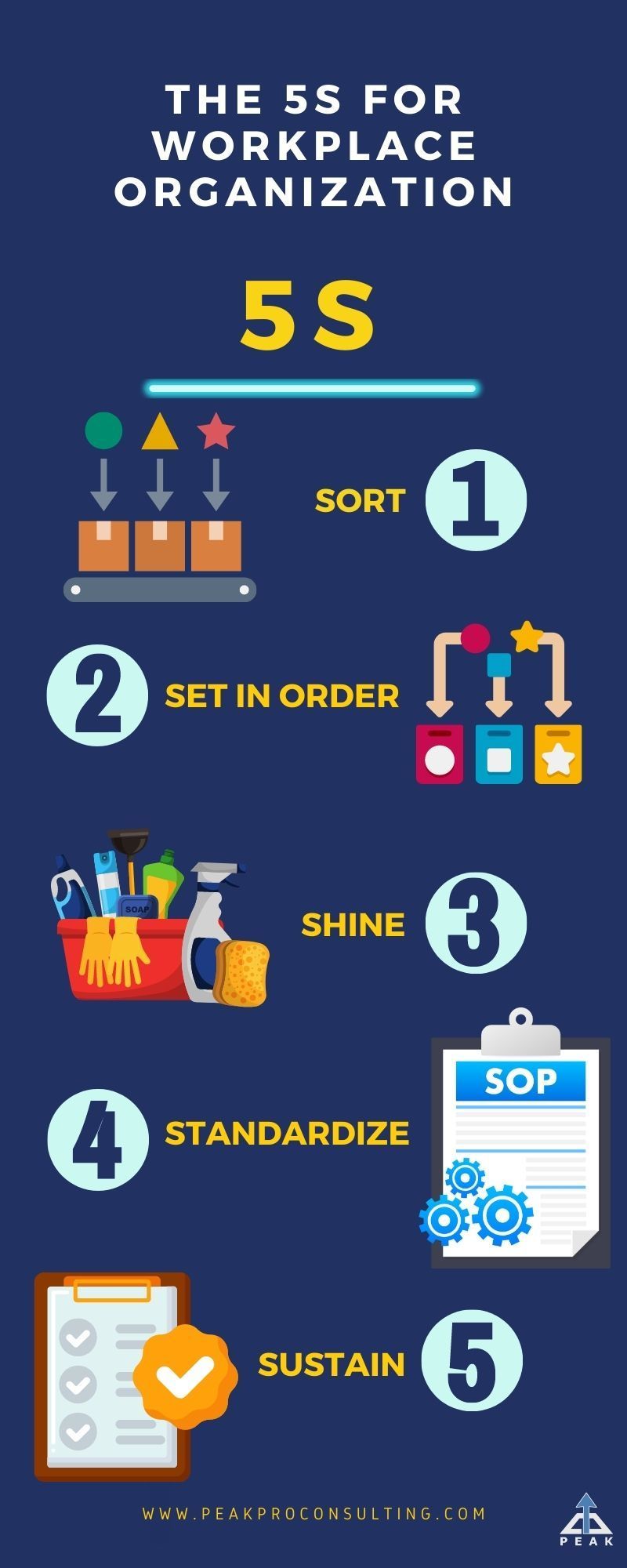

In part 3 of our series titled “Embracing Slower Times: Building Resilience for Long-Term Success, we look at the advantages of applying 5S and creating a workplace organization to set your organization up for long-term success. In this blog, I discuss the benefits of 5S and some of the pushbacks you may encounter when trying to deploy it during slower times.

What successes have you seen come from a proper deployment of a 5S journey? Please post your thoughts in the comments section.

To me, 5S is a tricky tool, not in implementation but in justification. It can be difficult to justify due to the low hard savings (ROI) paired with the time and resources needed to execute it well. There is no better time to start or reinvigorate a 5S journey than when things are slow since you have both the time and the resources available. That is why I have included it in the series “Embracing Slower Times: Building Resilience for Long-Term Success”.

5S is one of the foundational tools in the lean toolbox and a go-to for many companies. The reason it is so well-liked is that it is usually low-cost to implement, easy to teach and comprehend, creates quick results, and is flexible in time and resource requirements. It also allows an organization to see how well it sustains this straightforward tool, before jumping into other tools that are more challenging to implement and sustain. So, with all those positive attributes why is there pushback to deploy 5S when things are slow?

First, financially 5S doesn’t always have a big bottom-line impact. In fact, in some cases, it can negatively impact them in the short term. When you dispose of old obsolete inventory or machinery, it may hit the asset value, and thus create a negative result. Also, it takes employees to do 5S. When demand or production is low, it is less expensive to send people out than to have them work on 5S. In my opinion that is focusing on the short-term impact and misses a perfect opportunity to improve the safety and functionality of an area while increasing the value of employees through training and education. In a few situations, 5S will drive positive bottom-line impact like eliminating the need for rented overflow storage space or avoidance of footprint expansion by better maximizing the current footprint.

If you find the financials are a sticking point, do some homework. Are there any off-site storage or monthly rental like trailers/storage units/etc. that could be reduced or eliminated if space was available? Are there plans for expansion of the current footprint via building or moving that could be prevented if space was available? If your organization tracks soft savings, calculate the potential by using the current cost/square foot rate and show it as an avoided cost. I always like to include safety avoidance. Using the estimated cost associated with safety concerns, you could convert that into avoidance savings using your historical safety data.

Second, sustainment is hard! Sometimes organizations must continually go back and fix the areas that have completed 5S activities. If that happens, the organization should stop and address the sustainment issues before continuing with more 5S work. That will involve managing the issues that allow people to go back to the old way of doing things and requires building a process that eliminates this frustration pattern by deploying better standards, visuals, and ownership involvement.

Lack of ownership is very confusing for everyone. A manager may clearly understand who owns an area, but does everyone working in the area know? More importantly, does the owner know they are responsible for the area? These issues can be overcome by doing a couple of things before you begin the 5S activities. First, meet with everyone in the area and explain what 5S is and then establish clear expectations around maintaining the gains. Second, clearly communicate who the owner of the area is and help create a standard that incorporates them into the day-to-day review of the area.

In the past, I consulted with a hospital that wanted to start a 5S journey. The first 5S event was in a storage area. We met with the team to discuss the area, observe and document it with before photos and then we got to work. At the end of the event, we toured the area, reviewed the changes, and created standards (including pictures). Once the event finished the owner, using the standards created, inspected the room once a day at random times, and any issues were brought to the team for immediate resolution. After 6 months of daily follow-up by the owner, he was able to change to periodic review. Amazingly, the area continued to sustain the 5S even with fewer inspections by the owner. Everyone knew it was unacceptable for the area to not meet the standards.

I also had a similar outcome with a retail shop that applied 5S. By the end of the event, they were able to move out of an overflow storage space and cut their monthly rent by 25%. Yet another company cleared out space during a 5S event that allowed them to avoid expanding their square footage when a new product launched. I could go on and on with story after story.

So, should or shouldn’t a company work on 5S when business is slow? Absolutely. Providing knowledgeable employees with time to make improvements will lead to processes running smoother and as business demand begins to increase so will the benefits. A workspace that is neat, clean, and organized leads to improved safety and morale and reduces damage to supplies, lost inventory, and search time. You know the slogan: time is money. 5S is proven to save time, which saves money. Let me share one last example to show the power of 5S.

I worked with a manufacturing facility that was starting a lean journey and wanted to see how well it would be accepted within the organization’s culture. The area selected was called “the pit”. It was an interesting area with no clear purpose other than to collect stuff, like the kitchen drawer we all have! When I first met the team, I asked about the history of the area and its current purpose. A few people responded, “It was a storage area.” Another answered, “An overflow area.” My favorite, “Where things go to rot.” When I asked who owned the area, there was silence.

The first order of business was to photograph the area, followed by completing a time study. I asked employees familiar with the area to go pull items and tracked their time. It took 15 to 20 minutes; however, one person abandoned the search after 30 minutes. Over the next few days, the team got rid of obsolete or damaged parts, sorted out what items should stay and what should go, repaired shelves, cleaned the floors, and painted the walls. By

the end of the third day, you could see the impact. It was brighter, cleaner, safer, and much easier to get around.

At the end of the week, we brought the team and leaders together to review the changes and demonstrate the power of 5S. We selected a volunteer from the front office, who didn’t spend time any time in “the pit”, to test the 5S standards. She received minimum training and was sent on her way to find the part. We started the stopwatch and in less than 2 minutes she was back with the part in hand. The reduction in search time helped to reduce downtime in the assembly area, reduced replacement part requests, and improved output. There was a one-time negative cost impact due to the disposed of items, but based on the overall success, the company decided to continue its improvement journey.

If you're trying to do 5S and you're struggling to get people to buy in because there are no real savings, complete some time studies and convert it into time per day or week. Then ask if people would be happy with a 50% reduction. Count the number of obsolete and damaged parts or capture any overflow storage cost and see what a 50% reduction would save. All that data will provide support for spending the time and resources 5S’ing the area.

5S is a great tool that can be easily leveraged during a slow period. Scoping the area and work content to match the time given can make huge impacts over time. If it is done consistently and sustained, the financial ramifications will eventually appear. So go and look at areas that are full of stuff, that are messy, that are junky, and generally unloved. Those hold so much potential and are quietly waiting to be restored. You have the time, you have the resources, so go and do it!

- What are your thoughts on 5S?

- What type of improvements have you seen from 5S activities?

- How did you capture the cost savings or justify the 5S resources and time?

Would love to see your thoughts or questions in the comment section. If you would like more information on 5S feel free to reach out to me.

Peaks and Valleys.....